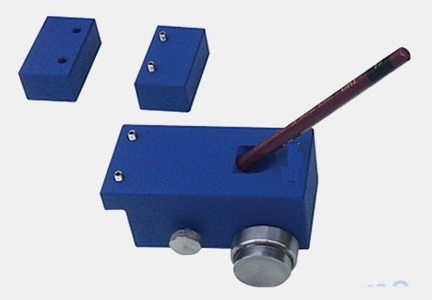

Adjustable Pencil Hardness Tester

Price 50 INR/ Piece

Adjustable Pencil Hardness Tester Specification

- Protection

- Corrosion-resistant Finish

- Capacity

- One Pencil at a Time

- Diameter

- Pencil Diameter: 6-6.5 mm Compatible

- Application Media

- Coated Surfaces, Paints, Varnishes

- Measurement Range

- 6B - 9H

- Temperature Range

- Ambient (Typically 5C to 40C)

- Humidity %

- Ambient (Typically 20% to 80% RH, Non-condensing)

- Equipment Type

- Pencil Hardness Tester

- Connectivity Type

- None (Manual)

- Resolution

- 1 Hardness Step (Based on Pencil Grade)

- Material

- Aluminum Alloy Body, Stainless Steel Components

- Power Supply

- Not Required (Manual Operation)

- Accuracy

- High, as per ISO 15184

- Display Type

- Analog (Visual Inspection)

- Range

- 6B to 9H (Standard Pencil Hardness Range)

- Packaging

- Supplied in Protective Carry Case

- Replaceable Parts

- Easily Replaceable Pencil Holder and Weights

- Sample Size

- Suitable for small panels or coated surfaces

- Test Angle

- Maintained at 45 degrees during test as per standard

- Dimensions

- Approx. 112 mm (Length) x 47 mm (Width) x 35 mm (Height)

- Roller Material

- Non-abrasive, Smooth Surface for Uniform Application

- Test Load

- Adjustable, typically 500g, 750g, 1000g (changeable weights included)

- Handle/Grip

- Ergonomic Knob for Smooth Movement

- Weight

- Approx. 500g to 1kg (with attachments)

Adjustable Pencil Hardness Tester Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

About Adjustable Pencil Hardness Tester

Technical Specification.

- Three points are touched on the tested surface (roller, pencil core)

- The angle between pencil and the tested surface is 45º

- Pressure of pencil lead is 500g,750g,1000g

Precision Testing for Coated Surfaces

Engineered to deliver accurate evaluation of film hardness, this tester supports a wide pencil hardness range from 6B to 9H. It complies with industry standards, making it ideal for manufacturers, traders, and service providers dealing with surface coatings or paints in India. Its ergonomic design ensures comfortable use during repeated tests.

Flexible & User-Friendly Design

Changeable weights and an adjustable load simplify the testing process, letting users configure the tester for different test requirements. The tester is compatible with standard pencils (66.5 mm diameter), and its easily replaceable parts extend product lifespan. A protective carry case is included, enhancing portability and safety during transport.

FAQs of Adjustable Pencil Hardness Tester:

Q: How is the test load adjusted on the pencil hardness tester?

A: The tester comes with changeable weights, allowing users to select test loads of 500g, 750g, or 1000g based on standard requirements. Weights can be easily replaced to suit specific coating hardness assessments.Q: What surfaces or materials can be evaluated with this device?

A: This tester is suitable for evaluating the hardness of coated surfaces such as paints, varnishes, and film coatings on small panels. It is widely used in quality control across manufacturing, distribution, and service sectors.Q: When should I replace the pencil holder or weights?

A: Components like the pencil holder and test weights are easily replaceable and should be changed if damaged, worn out, or when different load settings are required for testing.Q: Where can this tester be used effectively?

A: It is designed for ambient laboratory conditions, typically between 5C to 40C and 20%80% relative humidity. Its compact dimensions and portable carry case allow use in laboratories, production lines, or field service applications.Q: What is the process for conducting a hardness test?

A: To perform a test, insert a standard pencil into the holder, set the desired test load, place the sample panel, and move the tester smoothly across the surface at a maintained 45-degree angle. Hardness is determined visually by inspecting the trace left by the pencil.Q: How does ambient temperature and humidity affect operation?

A: The tester operates reliably in ambient environments, typically within 5C40C and 20%80% RH (non-condensing). Extreme conditions may affect material behavior, so standard laboratory environments are recommended for optimal accuracy.Q: What benefits does this tester provide to users in India?

A: Users benefit from high accuracy, compliance with ISO 15184, ergonomic handling, flexible configurations, and robust construction. It helps improve quality control, ensuring reliable product performance across a wide range of coatings and industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hardness Testers Category

Shore Hardness Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Resolution : 1 Shore unit

Accuracy : 1 Shore unit

Material : Highgrade stainless steel & alloy

Display Type : Other, Analog dial

Leeb Hardness Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Resolution : 1 HLD

Accuracy : 6HLD (0.8% @ HL=800)

Material : ABS plastic enclosure

Display Type : Other, LCD with backlight

Buchholz Indentation Tester

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Resolution : 0.01 mm

Accuracy : 0.01 mm

Material : Stainless steel body with hardened steel indenter

Display Type : Other, Analog Scale

Pencil Hardness Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 , , Unit

Resolution : 1 grade increment

Accuracy : High precision, up to 0.1 mm

Material : Stainless Steel, Aluminium Body

Display Type : Other, Analogue (No digital display)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS