Dial Thickness Gauge

Price 50 INR/ Piece

Dial Thickness Gauge Specification

- Sensor Type

- Mechanical Contact Point

- Temperature Range

- 0C to 40C

- Measurement Range

- 0-10 mm

- Protection

- Standard - No special environmental protection

- Resolution

- 0.01 mm

- Pressure Range

- Atmospheric

- Capacity

- Single Specimen / Single Point Measurement

- Application Media

- Metal, Glass, Film, Paper, Leather, Rubber, Sheet

- Humidity %

- Up to 80% RH (non-condensing)

- Diameter

- Measuring area: 10 mm

- Equipment Type

- Dial Thickness Gauge

- Material

- Stainless Steel / Hardened Steel Contacts

- Power Supply

- Manual (No power supply required)

- Accuracy

- 0.01 mm

- Display Type

- Analog (Dial)

- Range

- 0-10 mm

- Finish

- Polished / Chrome Plated

- Mounting

- Hand Held or Tabletop

- Operating Principle

- Spring Loaded Lever Mechanism

- Contact Point Shape

- Flat / Spherical depending on model

- Portable

- Yes - Hand Held

- Indicator Size

- Diameter approx. 50 mm

- Calibration

- Factory Calibrated, Adjustable

- Readout

- Clear Black Markings

- Measuring Force

- Less than 1 N

- Equipment Type

- Dial Thickness Gauge

Dial Thickness Gauge Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

About Dial Thickness Gauge

Precision Measurement Across Multiple Materials

Accurately measure thickness on various materials including metal, glass, film, paper, and rubber using the Dial Thickness Gauge. The adjustable contact point design and spring-loaded mechanism ensure consistently precise results, making it an essential tool for manufacturers, traders, and service providers.

Designed for Ease of Use and Portability

With its hand-held or tabletop mounting options and analog dial display, this gauge allows quick, manual operation without the need for a power supply. The polished or chrome finish and stainless steel construction enhance durability, giving users confidence in both laboratory and industrial settings.

FAQs of Dial Thickness Gauge:

Q: How does the Dial Thickness Gauge function?

A: The gauge uses a spring-loaded lever mechanism to enable precise single-point thickness measurement. When the contact point (flat or spherical) touches the specimen, the dial indicates the thickness with clear black markings.Q: What materials can I measure with this gauge?

A: You can measure the thickness of metals, glass, film, paper, leather, rubber, and sheet materials. Its versatile contact point and sensitivity make it suitable for diverse applications in manufacturing and quality control.Q: When should the gauge be calibrated or adjusted?

A: The Dial Thickness Gauge is factory calibrated for accuracy. Additional adjustments may be performed before use if required, especially after heavy usage or exposure to temperature changes, to ensure ongoing measurement reliability.Q: Where can this gauge be operated or installed?

A: Designed for hand-held use, it can also be mounted on a tabletop. Its robust construction allows you to use it in workshops, laboratories, production floors, or inspection roomsany environment needing precise thickness measurements.Q: What is the process for measuring specimen thickness?

A: Simply place the specimen between the contact point and anvil, press the lever, and read the measured thickness directly from the analog dial. Its mechanical operation requires no power supply, providing you with instant, reliable results.Q: What are the benefits of using this gauge for thickness measurement?

A: You benefit from high measurement accuracy (0.01 mm), clear analog display, effortless portability, and durable constructionensuring efficient quality control, reduced measurement errors, and versatility across different material types.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Cleanliness & Surface Profile Category

Testex Snap Gauge

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity % : Upto 85% RH (Noncondensing)

Display Type : Other, Analog Scale

Resolution : 0.01 mm

Accuracy : 0.01 mm

Testex Tape Press-O-Film

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity % : Up to 85% RH

Display Type : Other, None (manual optical measurement)

Resolution : 1 m

Accuracy : 10% of reading

Hypodermic Needle Pressure Gauge

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Humidity % : Up to 95% RH, noncondensing

Display Type : Other, Dial Gauge

Resolution : 1 psi

Accuracy : 2% of full scale

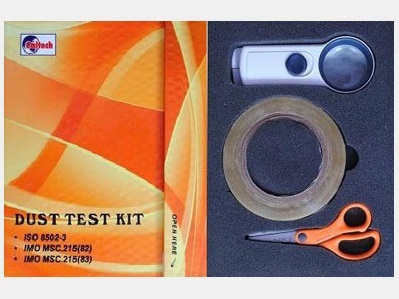

Dust Tape Test Kit

Price 50 INR / Kit

Minimum Order Quantity : 1 Kit

Humidity % : Operational in humidity up to 90%

Display Type : Other, No digital display

Resolution : Not defined

Accuracy : High accuracy for qualitative dust assessment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS