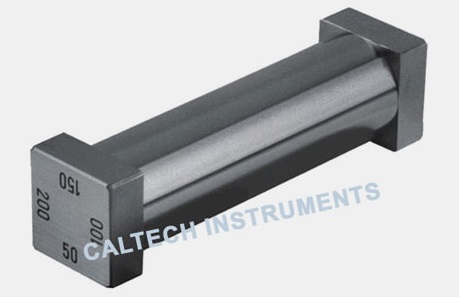

Film Applicator With Holding Device

Price 50 INR/ Unit

Film Applicator With Holding Device Specification

- Diameter

- Holding Device Fits up to 200 mm

- Measurement Range

- 10 mm to 300 mm (Film Width)

- Application Media

- Paint, Coating, Ink, Adhesives

- Temperature Range

- Ambient Operating Conditions

- Humidity %

- Suitable for Standard Lab Conditions

- Connectivity Type

- Manual (No Digital Connectivity)

- Capacity

- Single or Multiple Panel Holding

- Equipment Type

- Film Applicator with Holding Device

- Protection

- Corrosion Resistant

- Resolution

- Precision up to 0.01 mm (Film Thickness Adjustment)

- Material

- High-Grade Stainless Steel and Aluminium

- Power Supply

- Not Applicable (Manual Operation)

- Accuracy

- High Uniformity in Film Thickness

- Range

- Applicable for Standard Test Panels

- Adjustable Film Gap

- 10 to 500 microns

- Typical Industries

- Paint, Ink, Coating, Adhesive Manufacturing

- Weight

- Approx. 2.5 kg

- Panel Size Compatibility

- Up to 200 x 300 mm

- Holding Device Type

- Adjustable Clamping Mechanism

- Usage Area

- Laboratory and Industrial Quality Control

- Mounting

- Table Top Use

- Cleaning Method

- Wipeable, Chemical Resistant Parts

- Safety Features

- Non-Slip Base, Secure Holding Arms

- Accessories Included

- Interchangeable Applicator Bars

- Film Application Method

- Manual Spread with Even Pressure

- Finish

- Smooth, Easy-to-Clean Surface

Film Applicator With Holding Device Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, Australia, North America, Eastern Europe, Middle East, South America, Western Europe, Central America, Africa

- Main Domestic Market

- All India

About Film Applicator With Holding Device

Film Applicator With Holding Device

Caltech India Offers Film Applicator With Holding Device. To Enable Experimental Chemists Conveniently Draw Down Precise Coating Film On The Different Substrate, This Type Film Applicator Is Well-designed. It Greatly Improves The Reproducibility Of Paint Film.

Precision Film Application for Consistent Results

This applicator enables the manual and controlled spreading of coatings, ensuring high uniformity across the entire test panel. The adjustable gap and secure holding mechanism allow for precise film thickness control, vital for accurate quality testing in painting, ink, coating, and adhesive industries.

Built for Versatility and Durability

Constructed of high-grade, chemical-resistant stainless steel and aluminium, the device is ideal for repeated laboratory or industrial use. It handles a range of media and is compatible with various panel sizes. The wipeable and corrosion-resistant finish simplifies cleaning and maintenance.

User-Friendly and Safe Operation

Engineered for ease of use, the applicator features a non-slip base, secure holding arms, and is operated manuallyrequiring no external power. Accessories like interchangeable bars increase versatility, while the design ensures stable, safe application on any tabletop.

FAQs of Film Applicator With Holding Device:

Q: How does the adjustable clamping mechanism benefit film application?

A: The adjustable clamping mechanism securely holds test panels of various thicknesses and sizes, ensuring stability and uniform contact during manual film application. This feature enhances precision, producing consistent film layers even at different thickness settings.Q: What materials can be applied with this film applicator?

A: This device is suitable for applying a wide range of media, including paints, inks, adhesives, and various coatings. Its chemical resistance and robust construction make it ideal for demanding industrial and laboratory environments.Q: When should the interchangeable applicator bars be used?

A: Interchangeable applicator bars are used when different film thicknesses or application patterns are required. By swapping the bars, users can achieve precise control over the film gap, accommodating various test protocols or industry standards.Q: Where can this film applicator be used effectively?

A: It is ideal for laboratories and quality control departments in industries such as paint, ink, coating, and adhesive manufacturing. Its tabletop, non-electric design ensures easy integration into most lab and factory settings across India and beyond.Q: What is the process for cleaning and maintaining the device?

A: The applicators smooth, corrosion-resistant surface and chemical-resistant parts allow for simple cleaning by wiping with appropriate solvents. Regular cleaning after each use maintains performance and prevents contamination across tests.Q: How does the manual spread method ensure film thickness accuracy?

A: Manual spreading with even pressure, combined with the adjustable film gap and precision construction, enables the applicator to deliver films with high uniformity, achieving thickness accuracy up to 0.01 mm as per user settings.Q: What are the key benefits for industrial and laboratory users?

A: The main benefits include precise and reproducible film thickness, adaptability to various panel sizes and media, robust build quality for longevity, and safe, user-friendly features that streamline quality control workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bar Coaters & Film Applicators Tools Category

Leveling and Sagging Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 010 mm groove depth (12 channels)

Temperature Range : Ambient Conditions 10C to 45C

Accuracy : High, as per ISO 71, ASTM D4400 standards

Material : Stainless Steel frame with precisionground surface

Automatic Film Applicator

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Measurement Range : 05 mm

Temperature Range : Ambient: 5C to 40C

Accuracy : 0.01 mm

Material : Stainless steel and anodized aluminum

Four Sided Film Applicator

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 4 Different Preset Film Thickness Options

Temperature Range : Room Temperature Application

Accuracy : High Precision Film Application

Material : Highgrade Stainless Steel

Wire Bar Coaters

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 5 to 200 microns depending on wire

Temperature Range : Ambient temperature operation

Accuracy : 0.5 micron (Depends on proper usage)

Material : Stainless Steel (304/316 grade), with aluminium or wooden handles

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS