Through Coating Ultrasonic Thickness Gauge

Price 50 INR/ Piece

Through Coating Ultrasonic Thickness Gauge Specification

- Temperature Range

- -10C to 60C

- Application Media

- Metal, Coated Metals, Non-metals with Coating

- Equipment Type

- Through Coating Ultrasonic Thickness Gauge

- Frequency

- 5 MHz Standard Probe

- Resolution

- 0.01mm / 0.001 inch

- Measurement Range

- 0.8mm~300mm (in steel)

- Sensor Type

- Piezoelectric Ultrasonic

- Diameter

- Probe: 10mm (typically)

- Capacity

- Data Logging up to 500 Readings

- Connectivity Type

- USB (optional, for data transfer)

- Pressure Range

- Normal Atmospheric

- Humidity %

- <85% RH, Non-condensing

- Protection

- IP65 Splashproof Housing

- Material

- ABS Engineering Plastic

- Power Supply

- 2 x 1.5V AA Alkaline Batteries

- Power Consumption

- Approx. 50mW

- Accuracy

- (1%H+0.1)mm

- Display Type

- LCD Digital Display

- Range

- 0.8mm~300mm (in steel, depending on probe)

Through Coating Ultrasonic Thickness Gauge Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

About Through Coating Ultrasonic Thickness Gauge

Technical Specification

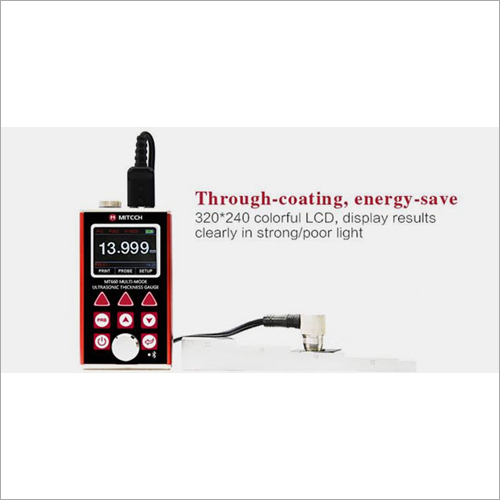

Model | MT-600 |

Display | 320240 TFT color LCD screen, adjustable backlight brightness |

Measuring Range | Two Working Modes: Pulse-Echo mode: (0.65600)mm (in Steel). Echo-Echo mode: (2.5100)mm |

Sound Velocity Range | 1000~9999 m/s |

Resolution | 0.1mm/0.01mm/0.001mm switchable |

Accuracy | (0.04mm (10mm): 0.4%H(>10mm) |

Units | Metric / English unit selectable |

Communication | Support Bluetooth and USB2.0 communication, the host program can be uploaded online |

Memory | Memory upto 100 files (upto 100 values for each file) of stored value |

Power Supply | Two AA size, 1.5 volt alkaline batteries. 100 hours typical operating time (EL backlight off) |

Dimension | 150 x 76 x 38 mm |

Net Weight | 295 g |

Measure Without Removing Coatings

This ultrasonic thickness gauge allows direct measurement of the base metal beneath coatings such as paint or varnish, eliminating the need for time-consuming surface preparation. The devices through coating function enhances workflow efficiency and preserves the integrity of the applied coating, making it ideal for inspection and quality assurance in various industries.

Precision and Convenience in One Device

Designed for versatility, the gauge supports user-adjustable velocity selection, enabling accurate measurements across diverse materials. The backlit LCD, 6-key soft-touch operation, and selectable units (mm/inch) streamline usage. With auto power-off and low power consumption, the device ensures extended field readiness. The rugged ABS plastic housing with IP65 splashproof protection makes it suitable for challenging environments.

FAQs of Through Coating Ultrasonic Thickness Gauge:

Q: How does the through coating measurement feature work on this ultrasonic thickness gauge?

A: The gauge uses ultrasonic pulses to penetrate through surface coatings, such as paints or varnishes, and measures only the base metal thickness. This eliminates the need to remove coatings before measurement, saving time and preserving the coatings condition.Q: What is the process for calibrating the device?

A: The gauge supports both single-point and two-point calibration modes. Users simply use calibration blocks or reference samples during setup to ensure measurement accuracy for various materials. Calibration can be quickly accessed and set using the gauges operating keypad.Q: When should I use the velocity adjustment function?

A: Velocity adjustment is useful when measuring different materials with varying sound velocities. The user can input the material-specific velocity (between 10009999 m/s) to enhance measurement precision for metals, plastics, or other coated substrates.Q: Where can this thickness gauge be effectively used?

A: This device is ideal for use in metal fabrication, shipbuilding, automotive maintenance, industrial inspection, and anywhere coated substrates require evaluation. Its portability, durability, and splashproof casing allow both indoor and outdoor operation across various industries.Q: What benefits does data logging provide with this model?

A: The built-in data logging function stores up to 500 readings, enabling users to maintain records for quality control, trend analysis, or reporting purposes. The optional USB connectivity facilitates convenient data transfer to a computer for further analysis.Q: How does the device ensure measurement accuracy in different environmental conditions?

A: Engineered with an ABS housing and IP65-rated splashproof protection, the gauge operates reliably in harsh conditions. It can be used within a temperature range of -10C to 60C and up to 85% non-condensing humidity, making it suitable for demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ultrasonic Category

Multi-Mode Ultrasonic Thickness Gauge

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Power Consumption : <50 mW

Application Media : Metals, Plastics, Ceramics, Glass, and other Ultrasonic Conductive Materials

Equipment Type : MultiMode Ultrasonic Thickness Gauge

Measurement Range : 0.75 mm to 300.0 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS