Digital Surface Profile Gauge

Price 50 INR/ Unit

Digital Surface Profile Gauge Specification

- Sensor Type

- Contact Type

- Measurement Range

- 0 800 m

- Resolution

- 1 m

- Temperature Range

- 0C to 40C

- Humidity %

- 85% RH (non-condensing)

- Material

- Stainless Steel and ABS Plastic

- Power Supply

- 1 x CR2032 battery

- Power Consumption

- Low

- Accuracy

- 5 m

- Display Type

- Large LCD Digital Display

- Range

- 0 to 800 m

Digital Surface Profile Gauge Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, South America, Asia, Central America

- Main Domestic Market

- All India

About Digital Surface Profile Gauge

Digital Surface Profile Gauge

Caltech india offers digital surface profile gauge for blasting. Digital surface profile gauge will allow the peak to valley height of blast cleaned surfaces to be accurately measured in accordance with the ASTM D4417 Standard. Caltechs digital surface profile gauge or needle gauge is highly useful and users friendly tool for paint, coating, and corrosion inspection. Surface profile gauge provides surface profile measuring technology for measuring profile on either flat or curved surfaces

The surface profile gauge is initially set to zero with the glass zero plate and the foot is then placed on the blasted profile. The foot sits on top of the peaks and the sharp stylus travels to the bottom of the valley, allowing the gauge to display the peak to valley height. A number of measurement can be made and the average taken.

Precision Measurement and Advanced Features

Engineered for consistent performance, this digital surface profile gauge employs a contact-type sensor with a hardened steel probe tip. Its auto/manual zero setting and high resolution enable precise surface assessments, critical for industries adhering to international standards. The large, backlit LCD ensures visibility, and handy functions like data hold and unit conversion maximize efficiency for users.

Durability and Ease of Operation

Constructed from stainless steel and ABS plastic, the gauge withstands rigorous field conditions. With an IP54 protection level, low power consumption, and single-handed operating method, its both robust and ergonomic. Its compact size and light weight enhance portability, making it convenient for quality control professionals working across various environments.

FAQs of Digital Surface Profile Gauge:

Q: How does the digital surface profile gauge measure surface roughness?

A: The gauge uses a digital contact measurement principle, where a hardened steel probe tip detects and records variations in surface profile. The readings are shown in real time on the large LCD display for immediate analysis.Q: What is the benefit of the auto power off and data hold functions?

A: The auto power off feature conserves battery life by turning off the device when not in use, while the data hold function allows users to freeze readings on the display, ensuring values can be easily recorded or referenced during inspection.Q: Where can this surface profile gauge be used effectively?

A: It is suitable for industrial environments requiring compliance with ASTM D4417 and ISO 8503-5 standards, such as manufacturing, quality control, painting, and coating inspections, both in laboratories and on-site locations.Q: When should the zero setting be adjusted, and how is it performed?

A: Zero setting should be performed before each series of measurements to ensure accuracy. This can be done manually or automatically according to user preference, aligning the gauge to the baseline surface level before assessment.Q: What is the process for switching between metric and imperial units?

A: The gauge features an easy-to-use unit conversion function, allowing users to switch between metric (m) and imperial measurements by toggling an accessible button on the device panel.Q: How does the gauge maintain accuracy in different environmental conditions?

A: With an operating temperature range of 0C to 40C and up to 85% relative humidity (non-condensing), plus IP54-rated protection, the device reliably provides accurate results in diverse industrial settings.Q: What are the main advantages of using this digital surface profile gauge for professional applications?

A: Its precision, compliance with global standards, ergonomic design, and robust construction make it ideal for professionals seeking reliable, repeatable, and quick surface measurement results in demanding work environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Cleanliness & Surface Profile Category

Pressure Blast Analyzer Gauge

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 0 to 200 psi

Display Type : Other, Analog Dial

Power Supply : 220V AC / 50 Hz

Humidity % : 0 to 95% RH

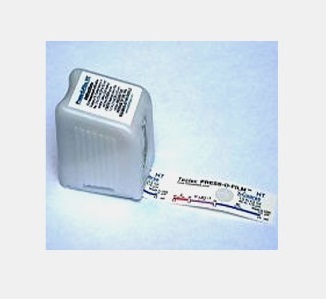

Testex Tape Press-O-Film

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 20 to 115 m (depends on tape grade)

Display Type : Other, None (manual optical measurement)

Power Supply : Not applicable (manual device)

Humidity % : Up to 85% RH

Dial Thickness Gauge

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Measurement Range : 010 mm

Display Type : Other, Analog (Dial)

Power Supply : Manual (No power supply required)

Humidity % : Up to 80% RH (noncondensing)

CSN Test Kit (Chloride, Sulphate & Nitrate Kit)

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : Chloride: 52000 mg/L, Sulphate: 101500 mg/L, Nitrate: 2500 mg/L

Display Type : Other, Visual Color Comparison

Power Supply : Not Required (Manual Kit)

Humidity % : Up to 90% RH (noncondensing)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS