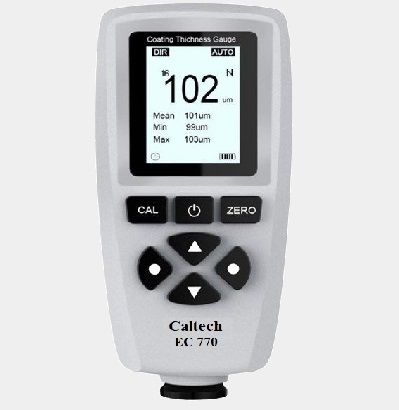

Coating Thickness Gauge Ferrous & Non Ferrous

Price 50 INR/ Unit

Coating Thickness Gauge Ferrous & Non Ferrous Specification

- Temperature Range

- 0C to 50C

- Application Media

- Ferrous & Non-Ferrous Surfaces

- Capacity

- Single and Multiple Measurement Modes

- Resolution

- 0.1 m

- Sensor Type

- Magnetic Induction (Ferrous), Eddy Current (Non-Ferrous)

- Diameter

- Probe Diameter: 12 mm

- Humidity %

- 90% RH

- Measurement Range

- 0-1250 m

- Connectivity Type

- No Connectivity

- Protection

- IP54 Rated

- Equipment Type

- Coating Thickness Gauge

- Material

- ABS Plastic

- Power Supply

- 2 x 1.5V AAA Batteries

- Power Consumption

- Below 20mA

- Accuracy

- 2% of reading

- Display Type

- Digital LCD Display

- Range

- 0-1250 m (0-50 mil)

- Operating Principle

- Magnetic and Eddy Current dual technology

- Calibration

- Includes zero and foil calibration modes

- Weight

- Approx. 90 g (including batteries)

- Backlight

- Yes (Display Backlight Provided)

- Dimensions

- 110 x 53 x 24 mm

- Minimum Substrate Thickness

- 0.5 mm

- Operating Language

- English

- Data Storage

- Up to 99 readings memory

- Auto Power Off

- Yes, after 3 minutes of inactivity

- Packaging

- Supplied with standard accessories and user manual

- Minimum Sample Area

- 6 mm x 6 mm

Coating Thickness Gauge Ferrous & Non Ferrous Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Coating Thickness Gauge Ferrous & Non Ferrous

Coating Thickness Gauge Ferrous & Non Ferrous

Coating Thickness Gauge utilize non-destructive priciple with most eonomical choice that retains the uncompromising quality of Coating Inspection Instruments. We are largest seller of coating thickness gauge in India.

Caltech Engineering Services India offers CM-8826 Digital Coating Thickness Meter with F & N probes.

CM-8826 coating thickness gauge has dual technology features selection of magnetic induction or eddy current measurement techniques. Coating thickness gauge is a portable measuring instrument, can take fast, intact, precise measurement of coating thickness. It can not only be used in engineering field, laboratories, but also meet the demand of multiple measuring by using two separate probes for ferrous and non-ferrous substrates.

Dual Technology for Versatile Applications

Equipped with both magnetic induction and eddy current sensors, this gauge accurately measures coating thickness on ferrous (iron, steel) and non-ferrous (aluminum, copper, etc.) surfaces. This dual operating principle expands usability across various industrial environments, making it suitable for quality control, manufacturing, and engineering workshops.

User-Friendly Digital Display and Data Storage

The digital LCD with backlight ensures readability in dim environments, while the devices memory stores up to 99 readings for hassle-free data management. With automatic power-off after three minutes of inactivity and simple calibration modes, users save both time and energy during field operations.

Accurate and Reliable Performance

Offering 2% accuracy and a wide measurement range from 0 to 1250 m, this gauge is engineered to meet the demands of critical coating inspections. With IP54 protection and lightweight ABS construction, the device is durable for frequent use on job sites or in laboratories.

FAQs of Coating Thickness Gauge Ferrous & Non Ferrous:

Q: How do I use the Coating Thickness Gauge on different surfaces?

A: You can measure coatings on both ferrous and non-ferrous materials. The gauge automatically detects the surface type and applies magnetic induction for ferrous substrates or eddy current for non-ferrous ones. Simply ensure the area is at least 6 mm x 6 mm and the substrate is thicker than 0.5 mm for accurate readings.Q: What is the benefit of the data storage feature in this gauge?

A: The built-in memory allows you to store up to 99 readings, making it easy to record and retrieve multiple measurement results onsite without needing external devices. This is particularly useful for quality assurance, record-keeping, and batch inspection tasks.Q: When should I perform calibration on the gauge?

A: Calibration is recommended when first using the device, after changing the probe, or if you observe measurement inconsistencies. Use zero or foil calibration modes as per the user manual to ensure ongoing measurement precision.Q: What process should I follow for routine measurement?

A: Make sure the surface is clean and dry, calibrate the device as needed, and press the probe against the sample. The digital LCD will display the coating thickness in m or mil for each measurement taken.Q: Where can this coating thickness gauge be used?

A: This gauge is suitable for use in factories, workshops, on-site inspections, and laboratories. Its portable size, IP54 protection, and broad temperature and humidity tolerance make it ideal for various industrial and field environments across India.Q: What are the main advantages of this equipment for dealers and service providers?

A: Dealers and service providers gain a reliable and versatile tool with quick, accurate measuring capabilities for both ferrous and non-ferrous coatings. Data storage, user-driven calibration, and robust protection enhance its value, supporting customer satisfaction and comprehensive service delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Film Thickness Category

Ferrite Meter

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Sensor Type : Magnetic Induction Probe

Resolution : 0.1 Fn

Power Supply : 9V Battery

Temperature Range : 0C to 50C

Plating Thickness Meter

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Sensor Type : Electromagnetic & Eddy Current

Resolution : 1 m

Power Supply : AC 220V 10% 50Hz

Temperature Range : 0C to 50C

Paint Film Thickness Meter

Price 50 INR / Unit

Minimum Order Quantity : 1 , , Unit

Sensor Type : Electromagnetic induction & eddy current

Resolution : 1 m

Power Supply : 1 x 1.5V AAA battery

Temperature Range : 0C to 40C

Coating Thickness Gauge - NF

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Sensor Type : Eddy current

Resolution : 1 m

Power Supply : 2 x 1.5V AAA batteries

Temperature Range : 0C~40C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS