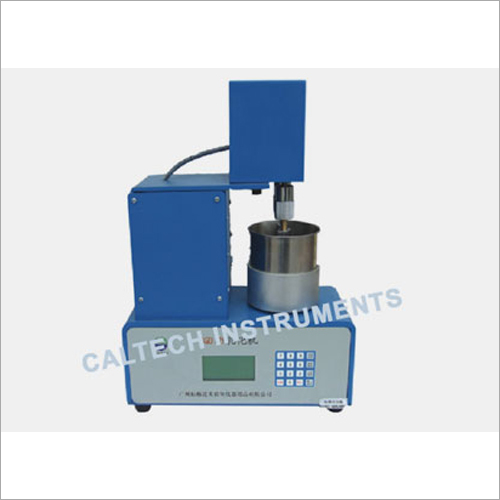

Digital Emulsification Tester

Price 50 INR/ Piece

Digital Emulsification Tester Specification

- Equipment Type

- Digital Emulsification Tester

- Frequency

- 50 Hz

- Diameter

- 50 mm sample tube

- Resolution

- 0.1 sec

- Capacity

- 1 Sample per Test

- Application Media

- Oil, Water, Chemical Emulsions

- Measurement Range

- Up to 99.9 seconds

- Current Range

- 0.1-2A

- Protection

- Overload and Short Circuit Protection

- Temperature Range

- Ambient to 100C

- Pressure Range

- Atmospheric

- Humidity %

- 0-90% RH (non-condensing)

- Sensor Type

- Electronic Timer Sensor

- Material

- Stainless Steel body

- Power Supply

- 230V AC, 50Hz

- Power Consumption

- 15 W

- Accuracy

- 1% of Reading

- Display Type

- Digital LED Display

- Range

- 0 to 99.9 sec

- Operation

- Automatic & Manual Modes

- Calibration

- Factory Calibrated

- Alarm

- Audio Visual indication at end of cycle

- Testing Standard

- Meets IS and ASTM standards

- Mounting Type

- Bench Top

- Timer Control

- Microprocessor based

- Sample Holder Material

- Borosilicate Glass

- Weight

- 8 kg (approx)

- Finish

- Corrosion Resistant Coating

- Warm-Up Time

- Less than 1 min

- Safety Features

- Splash proof Housing, Fuse protected

- Equipment Type

- Digital Emulsification Tester

- Operating Environment

- Laboratory/Field Use

Digital Emulsification Tester Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

About Digital Emulsification Tester

Technical Specification

- Power SupplyAC220V 50HZ

- Stirring Rotating Speed90/100/150 r. p. m

- Container SizeInner Diameter Height100100mm

- Stirrer rake Sizew h56100mm

- Overall Size330150460mm

- Weight20kg

Microprocessor-Based Timer with Dual Operation Modes

Our Digital Emulsification Tester features advanced microprocessor technology, allowing you to operate the device in either automatic or manual mode depending on your testing requirements. The intuitive LED digital display and electronic timer sensor ensure measurements are precise and easy to monitor. This sophistication makes emulsification testing both efficient and user-friendly, with a focus on practical lab or field applications.

Built-In Safety and Durability

Safety and longevity are at the core of this instruments design. The tester is housed in a splash-proof, corrosion-resistant stainless steel body, and equipped with fuse protection along with overload and short-circuit safety measures. These features make it reliable for regular use in demanding environments while safeguarding both the equipment and the user.

Standards-Compliant and Factory Calibrated

Every unit is calibrated at the factory and adheres to established IS and ASTM testing standards. This ensures you receive consistent, trustworthy results for critical emulsification testing, whether for research, quality control, or industrial purposes. The Borosilicate glass sample holder and robust build further guarantee dependable, repeatable measurements.

FAQs of Digital Emulsification Tester:

Q: How do I operate the Digital Emulsification Tester in automatic and manual modes?

A: To use the tester in automatic mode, select the auto setting and program your desired cycle duration on the digital LED display; the device will run the test without manual intervention. For manual operation, toggle to manual mode to control the testing process hands-on as needed. Both options are user-friendly and tailored for versatility in laboratory or field settings.Q: What safety features are included to protect both the user and the device?

A: The emulsification tester is equipped with a splash-proof housing, fuse protection, and built-in overload and short-circuit safeguards. These features provide multiple layers of protection, ensuring safe and trouble-free operation under a wide range of environmental conditions.Q: When and where is this tester typically used?

A: This instrument is suitable for laboratory and field use, making it ideal for quality control, research, and process monitoring in oil, water, and chemical emulsion testing. Its robust design allows reliable performance in atmospheric pressure conditions and a wide temperature and humidity range.Q: What materials is the tester constructed from, and how does this benefit users?

A: The main body is made of durable stainless steel with a corrosion-resistant coating, and the sample holder is crafted from Borosilicate glass. This construction enhances longevity, simplifies cleaning, and ensures sample integrity during testing.Q: How do the calibration and testing standards enhance the reliability of results?

A: Each unit is factory calibrated and meets international IS and ASTM testing standards, ensuring precise and consistent readings. This compliance allows users to trust the data for quality assurance, regulatory submissions, or research purposes.Q: What is the process for conducting a test with this emulsification tester?

A: Place the sample in the Borosilicate glass holder and select your desired time, mode, and parameters on the digital LED display. Initiate the test, and the machine will process according to the chosen settings. At the end of the cycle, the tester provides an audio-visual indication for user notification.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ink and Printing Instruments Category

Rub Resistance Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : Single specimen

Display Type : Other, Digital Cycle Counter

Material : Mild Steel with powder coated finish

Frequency : 50 Hz

Electron Ink Viscometer

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Capacity : 600 ml sample container

Display Type : Other, LED digital display

Material : Stainless Steel

Frequency : 50 Hz

Multi-Section Ink Proofing Press

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : Single & Multiple Section Proofing

Display Type : Other, Analog

Material : Stainless Steel & Hard Chrome

Frequency : 50 Hz

Electronic Viscometer

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Capacity : Sample Volume: 2050 ml

Display Type : Other, Digital LCD

Material : Stainless Steel, ABS Body

Frequency : 50 Hz

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS