Multi-Mode Ultrasonic Thickness Gauge

Price 50 INR/ Piece

Multi-Mode Ultrasonic Thickness Gauge Specification

- Measurement Range

- 0.75 mm to 300.0 mm

- Temperature Range

- -10C to +60C

- Diameter

- Standard Probe Diameter: 10 mm

- Equipment Type

- Multi-Mode Ultrasonic Thickness Gauge

- Protection

- IP54 splash proof

- Capacity

- Data Storage for up to 500 Readings

- Resolution

- 0.01 mm

- Pressure Range

- Standard Atmospheric Pressure

- Sensor Type

- Piezoelectric Ultrasonic Probe

- Connectivity Type

- USB for Data Transfer

- Humidity %

- 90% RH

- Frequency

- 2 MHz / 5 MHz / 10 MHz Selectable

- Application Media

- Metals, Plastics, Ceramics, Glass, and other Ultrasonic Conductive Materials

- Material

- ABS Engineering Plastic Housing

- Power Supply

- 2 x 1.5V AA batteries

- Power Consumption

- <50 mW

- Accuracy

- 0.05 mm + 0.5% H

- Display Type

- LCD Digital Display with Backlight

- Range

- 0.75 mm ~ 300.0 mm (in steel)

Multi-Mode Ultrasonic Thickness Gauge Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

About Multi-Mode Ultrasonic Thickness Gauge

Technical Specification

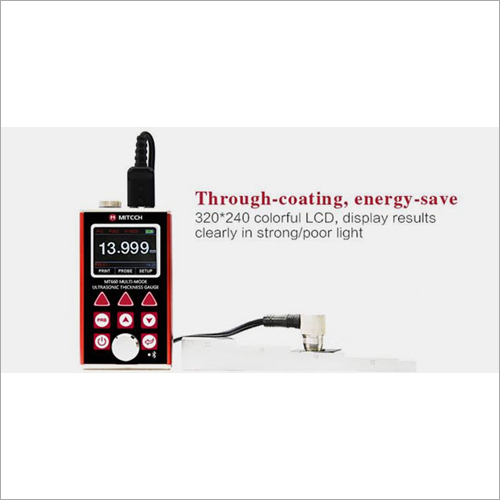

Model | MT-660 |

Display | 320240 TFT color LCD screen, adjustable backlight brightness |

Measuring Range | Two Working Modes: Pulse-Echo mode: (0.65600)mm (in Steel). Echo-Echo mode: (3100)mm |

Sound Velocity Range | 1000~9999 m/s |

Resolution | 0.1mm/0.01mm/0.001mm switchable |

Accuracy | (0.04mm (10mm): 0.4%H(>10mm) |

Calibration | Zero Point Calibration, Two Point Calibration |

Working Modes | Single Point Measurement, scan model measurement min/max measurement, differential measurement |

Units | Metric / English unit selectable |

Memory | Memory upto 100 files (upto 100 values for each file) of stored value |

Communication Interface | Support Bluetooth and USB2.0 communication, the host program can be uploaded online |

Data Printing | Capable of measuring Standard prtable Bluetooth thermal printer to print the measurement report |

Power Supply | Two AA size, 1.5 volt alkaline batteries. 100 hours typical operating time (EL backlight off) |

Automatic | It has auto screen standby, auto sleep, auto shutdown and other power saving functions. |

Material | Aluminium magnesium Alloy |

Dimension | 120 x 67 x 31 mm |

Net Weight | 317 g |

Advanced Measurement Modes for Multiple Applications

Switch easily between Echo-Echo (E-E) and Pulse-Echo (P-E) modes to suit a variety of inspection requirements, allowing users to measure through coatings or directly on the base material. This flexibility ensures accurate readings on metals, plastics, ceramics, glass, and other ultrasonically conductive materials.

Robust Design for Enhanced Durability

Built with an ABS engineering plastic housing and IP54 splash proof protection, this thickness gauge is designed to withstand demanding industrial conditions. The compact, lightweight build and carrying case make it convenient for fieldwork or daily use across various environments.

Comprehensive Data Management and Connectivity

Capture and store up to 500 readings with onboard memory, and utilize the USB or RS232 interface for seamless data transfer. Whether for manufacturing, quality assurance, or research, the gauges data output options enhance productivity and record-keeping.

FAQs of Multi-Mode Ultrasonic Thickness Gauge:

Q: How do I calibrate the Multi-Mode Ultrasonic Thickness Gauge for accurate measurements?

A: Calibration is straightforward with the options for 1-point, 2-point, or known thickness calibration methods. Use the provided calibration block and follow the instruction manual to ensure measurements are precise and reliable before use on your specific material.Q: What materials can be measured with this ultrasonic thickness gauge?

A: This device can accurately measure a broad range of materials including metals, plastics, ceramics, glass, and most ultrasonic conductive materials, making it suitable for various industrial applications.Q: When should I use Echo-Echo (E-E) versus Pulse-Echo (P-E) modes?

A: Use Echo-Echo (E-E) mode when you need to measure material thickness through coatings, paint, or layers. Pulse-Echo (P-E) is ideal for direct measurements on uncoated surfaces or where coatings are not present.Q: What is the process for exporting data from the device?

A: You can export stored data using either the USB or RS232 interfaces. Simply connect the gauge to your computer or compatible device and follow the instructions for data transfer included in the manual.Q: Where is this ultrasonic thickness gauge ideal to use?

A: It is suitable for use in manufacturing plants, quality control laboratories, field inspection sites, and anywhere material thickness measurements of metals, plastics, ceramics, or glass are required.Q: How does the thickness alarm function benefit my workflow?

A: The high/low thickness alarm feature alerts you when measurements exceed specified limits, helping ensure product quality and process consistency without constant monitoring.Q: What advantages do the auto power-off and long battery life features offer?

A: With auto power-off after 5 minutes of inactivity and up to 100 hours of battery life (with the backlight off), the gauge conserves energy and reduces the frequency of battery replacements, supporting extended field operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ultrasonic Category

Through Coating Ultrasonic Thickness Gauge

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Diameter : Probe: 10mm (typically)

Accuracy : (1%H+0.1)mm

Equipment Type : Through Coating Ultrasonic Thickness Gauge

Measurement Range : 0.8mm~300mm (in steel)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS