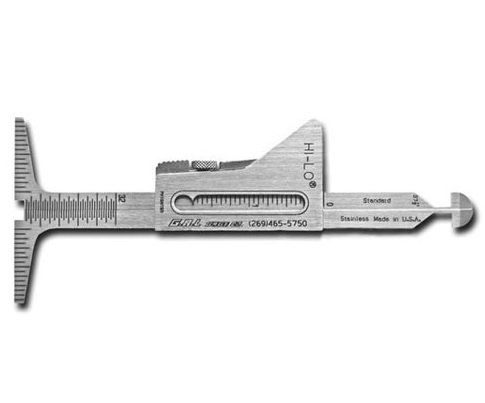

Hi Lo Welding Gauge

Price 50 INR/ Unit

Hi Lo Welding Gauge Specification

- Case

- Stainless Steel Compact Case

- Outer Size

- Pocket Size

- Measuring Range

- 1/16 to 1 (1.6mm to 25.4mm)

- Sensor Type

- Manual Measurement

- Display

- Analog Scale Engraved

- Material

- Stainless Steel

- Grade

- Industrial

- Application

- Weld Inspection: Internal Alignment, Weld Height, Misalignment, Fillet Size

- Accuracy

- 1/32 (0.8mm)

- Operation Type

- Manual

- Portable

- Yes

- Weight

- Approx. 45g

- Calibration

- Pre-calibrated

- Surface Finish

- Satin

- Corrosion Resistance

- High

- Blade Thickness

- 1.2mm

- Complies With

- AWS Specifications

- Scale Graduation

- Laser Engraved Metric & Imperial

Hi Lo Welding Gauge Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Hi Lo Welding Gauge

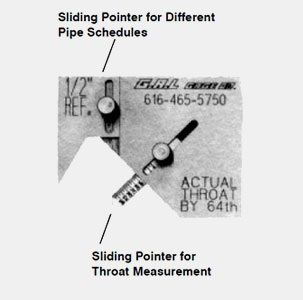

- Hi Lo Welding Gauge MEASURES INTERNAL ALIGNMENT of pipe after fit-up / alignment, cuts radiographic rejects.

- Hi Lo Welding Gauge measures internal misalignment of pipe before and after tacking.

- Hi Lo Gauge Measurements read in standard one side, and metric on the opposite side.

Reliable Weld Inspection Solution

Engineered for weld professionals, the Hi Lo Welding Gauge offers accurate internal alignment and quick verification of misalignments and weld height. Its durable construction supports consistent precision, making it a valuable addition to any industrial toolkit.

Versatile and User-Friendly Design

With both metric and imperial scales laser-engraved for visibility, this gauge provides straightforward manual operation. Its lightweight build and pocket-size format ensure ease of transport and convenient onsite use.

Built to Last in Heavy-Duty Environments

Made with stainless steel and featuring high corrosion resistance, the gauge stands up to demanding conditions. The satin finish adds durability while the calibration to AWS specifications assures industry-standard reliability.

FAQs of Hi Lo Welding Gauge:

Q: How does the Hi Lo Welding Gauge ensure measurement accuracy for weld inspections?

A: The gauge is pre-calibrated to AWS specifications, features laser-engraved analog scales for both metric and imperial measurements, and provides accuracy within 1/32 (0.8mm), making it highly reliable for industrial weld assessments.Q: What is the recommended process for using the Hi Lo Welding Gauge in the field?

A: To use the gauge, simply align it manually against the weld to assess parameters such as internal alignment, weld height, misalignment, and fillet size. Its analog scale allows quick readings, requiring no electronic setup or calibration before use.Q: When should I deploy this welding gauge instead of other measurement tools?

A: This gauge is ideal for situations requiring portable, rapid, and accurate manual weld measurements, especially when compliance with AWS standards and resistance to corrosion are critical factors.Q: Where can the Hi Lo Welding Gauge be effectively used?

A: Its compact, pocket-sized build makes it suitable for a range of industrial environments, including field inspections, workshops, and manufacturing plants where weld quality must be monitored consistently.Q: What benefits does the satin-finished stainless steel construction provide?

A: The satin-finished stainless steel offers excellent corrosion resistance and durability, ensuring long-term performance while withstanding exposure to harsh industrial conditions.Q: Is the gauge compatible with both metric and imperial measurement systems?

A: Yes, the gauges scale graduations are laser-engraved and clearly marked in both metric and imperial units, facilitating global use and versatility for various standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gauges Category

Mini Sub Gauge

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Display : Analog Dial

Outer Size : 36 mm Diameter

Material : Brass and Phosphor Bronze

Grade : Industrial Grade

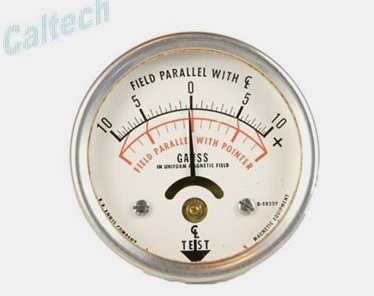

Gauss Meter

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Display : 3 1/2 Digit LCD Display

Outer Size : 165mm x 80mm x 30mm (approx.)

Material : High Impact ABS Plastic Body

Grade : Industrial

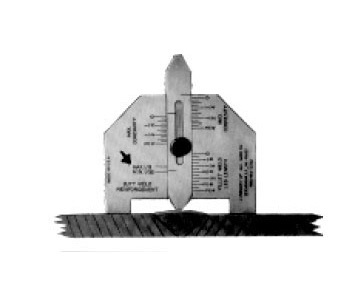

Automatic Weld Size Gauge

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Display : Analog Scale

Outer Size : 150mm

Material : Stainless Steel / Hardened Steel

Grade : Industrial

Mini Fillet Weld Keys

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Display : Etched Size Markings

Outer Size : Compact, Pocket Size

Material : Stainless Steel

Grade : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS