Leveling and Sagging Tester

Price 50 INR/ Unit

Leveling and Sagging Tester Specification

- Pressure Range

- Atmospheric only (Not pressurized)

- Temperature Range

- Ambient Conditions 10C to 45C

- Application Media

- Paints, Coatings, Varnishes

- Resolution

- 1 mm graduation

- Protection

- Corrosion-Resistant Coating

- Capacity

- 12 distinct channels for simultaneous test strips

- Equipment Type

- Leveling and Sagging Tester

- Measurement Range

- 010 mm groove depth (12 channels)

- Humidity %

- Up to 85% RH non-condensing

- Sensor Type

- Optical (Visual Sag/Level Observation)

- Connectivity Type

- Manual / Standalone (No Electronic Interface)

- Material

- Stainless Steel frame with precision-ground surface

- Power Supply

- Not Applicable (Manual Operation)

- Power Consumption

- Not Applicable (Manual Instrument)

- Accuracy

- High, as per ISO 7-1, ASTM D4400 standards

- Display Type

- Not Applicable (Direct Visual Assessment)

- Range

- 0-10 mm (Sagging and Leveling measurement)

- Use Environment

- Laboratory or Quality Control Areas

- Groove Width

- 6 mm (as per standards)

- Mounting

- Flat surface placement, non-slip feet included

- Sample Application Method

- Applicator Bar (Not included)

- Test Panel Dimensions

- approx. 170 mm × 80 mm

- Weight

- Approx. 600 g

- Cleaning

- Easy to clean with standard solvents

- Finish

- Polished stainless steel with etched graduations

Leveling and Sagging Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, South America, Eastern Europe, Western Europe, Middle East, Central America, North America, Australia, Africa

- Main Domestic Market

- All India

About Leveling and Sagging Tester

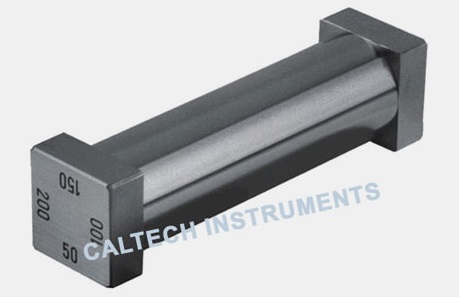

Leveling and Sagging Tester

Caltech india offers Sagging Tester. BGD 225 Sagging Tester produced by our company is in accordance with the specification of ASTM D4400 and ASTM D373. They are made of corrosion resistant stainless steel, the width of application is 75mm at 6mm per sagging thickness, and the gaps are being separated by a 1mm space as a marking on each sagging for distinctive identification of each sagging.

Effortless Performance Assessment

This tester allows users to effortlessly gauge both leveling and sagging properties of liquid samples across 12 precision-ground grooves. Each groove is clearly marked, allowing simultaneous assessment for consistent and reliable quality control. Ideal for manufacturers, suppliers, and research laboratories, it provides dependable results that inform production decisions.

Durable and Easy to Maintain

Crafted with corrosion-resistant, polished stainless steel, the tester is built to withstand repeated use in laboratory and industrial settings. The surface is easy to clean with standard solvents, ensuring maintenance takes minimal effort. The non-slip feet and flat surface design ensure safe and stable operation during routine tests.

Manual, Hassle-Free Operation

Requiring no electronic power or connectivity, this leveling and sagging tester supports manual operation for quick setup and deployment. Its straightforward, visual observation process minimizes training requirements while maximizing accuracy, making it ideal for both established laboratories and new quality control setups.

FAQs of Leveling and Sagging Tester:

Q: How does the Leveling and Sagging Tester work?

A: The tester operates by applying paints, coatings, or varnishes to a test panel using an applicator bar across twelve grooves, each 6 mm wide. As the sample dries, users perform a direct visual assessment to measure the degree of leveling and sagging according to the 010 mm graduations.Q: What types of substances can be tested with this equipment?

A: It is suitable for testing the leveling and sag resistance of a range of application media, including paints, coatings, and varnishes, as specified by international standards like ISO 7-1 and ASTM D4400.Q: When should I use the Leveling and Sagging Tester in my workflow?

A: Use the tester during laboratory evaluations or quality control stages to ensure paints and coatings meet required performance standards before final application or commercial release.Q: Where is this tester best utilized?

A: This tester is designed for laboratory environments and quality control areas where accurate, repeatable assessment of product rheology is required.Q: What are the cleaning and maintenance requirements for this instrument?

A: After each test, simply clean the polished stainless steel frame using standard laboratory solvents. Its corrosion-resistant finish and design make maintenance straightforward and quick.Q: What benefits does this manual tester offer over electronic alternatives?

A: The manual design eliminates the need for power supply or electronic interfaces, resulting in reliable, error-free assessments with minimal setup. It provides high accuracy and is easy to operate and maintain, ensuring dependable measurements in a variety of ambient conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bar Coaters & Film Applicators Tools Category

Automatic Film Applicator

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Temperature Range : Ambient: 5C to 40C

Accuracy : 0.01 mm

Measurement Range : 05 mm

Equipment Type : Automatic Film Applicator

Film Applicator With Holding Device

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature Range : Ambient Operating Conditions

Accuracy : High Uniformity in Film Thickness

Measurement Range : 10 mm to 300 mm (Film Width)

Equipment Type : Film Applicator with Holding Device

Four Sided Film Applicator

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature Range : Room Temperature Application

Accuracy : High Precision Film Application

Measurement Range : 4 Different Preset Film Thickness Options

Equipment Type : Four Sided Film Applicator

Wire Bar Coaters

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature Range : Ambient temperature operation

Accuracy : 0.5 micron (Depends on proper usage)

Measurement Range : 5 to 200 microns depending on wire

Equipment Type : Wire Bar Coater

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS