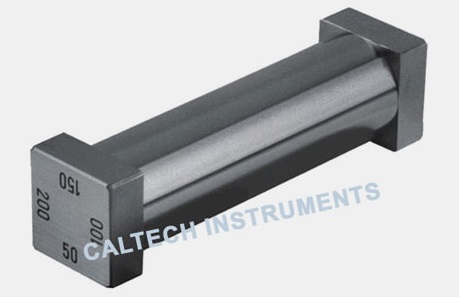

Wire Bar Coaters

Price 50 INR/ Unit

Wire Bar Coaters Specification

- Diameter

- Standard wire diameters: 5 to 200 microns

- Temperature Range

- Ambient temperature operation

- Equipment Type

- Wire Bar Coater

- Measurement Range

- 5 to 200 microns depending on wire

- Resolution

- 1 micron

- Protection

- Corrosion resistant with proper maintenance

- Capacity

- Width up to 400 mm (custom sizes available)

- Application Media

- Paints, coatings, inks, adhesives, varnishes, wet films

- Material

- Stainless Steel (304/316 grade), with aluminium or wooden handles

- Power Supply

- Manual Operation (No Power Required)

- Accuracy

- 0.5 micron (Depends on proper usage)

- Range

- Film thickness from 5 microns up to 200 microns (Depending on wire size)

- Optional Accessories

- Stand, cleaning brush, storage case

- Usage

- Ideal for laboratory R&D, quality control, and producing uniform coatings

- Cleaning

- Easily cleaned with suitable solvents

- Wire Material

- Precision stainless steel wire wound on solid rod

- Compliance

- Conforms to international quality standards (ISO, ASTM where applicable)

- Finish

- Smooth, uniform, burr-free finish

- Coating Width

- 100 mm, 200 mm, 300 mm, 400 mm (Customizable)

- Handle Type

- Ergonomic grip aluminium or hardwood

- Customization

- Custom diameters and lengths on request

Wire Bar Coaters Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, South America, Western Europe, Asia, Africa

- Main Domestic Market

- All India

About Wire Bar Coaters

Precision Coating for Laboratory Applications

Achieve highly uniform film coatings with our Wire Bar Coaters, specifically engineered for research, development, and quality control environments. The stainless steel wire design delivers consistent thickness for paints, adhesives, and more. Options for customizable widths ensure compatibility with various application needs.

Ergonomic Design and Superior Finish

Designed with user comfort in mind, these coaters incorporate aluminium or hardwood handles that are ergonomically shaped. Each unit features a smooth, burr-free finish for easy handling and efficient operation. The corrosion-resistant materials provide long-lasting durability in lab settings.

Customization and Accessories

Wire Bar Coaters can be tailored to your specific requirements with custom wire diameters and rod lengths. Optional accessories like stands, cleaning brushes, and storage cases enhance usability and maintenance. Each unit is built to international standards (ISO, ASTM where applicable) for dependable performance.

FAQs of Wire Bar Coaters:

Q: How do I use a Wire Bar Coater to achieve uniform coatings?

A: To use a Wire Bar Coater, evenly distribute your liquid media (such as paint or ink) across the substrate. Gently draw the coater over the surface with a steady hand to ensure uniformity. Film thickness depends on the wire diameter, ranging from 5 to 200 microns, and optimal technique ensures accuracy up to 0.5 micron.Q: What materials can be coated using this equipment?

A: Wire Bar Coaters are suitable for a wide range of media including paints, coatings, inks, adhesives, varnishes, and other wet films. The high-grade stainless steel construction resists corrosion for reliable performance across various laboratory and industrial applications.Q: When is customization of wire diameter or coating width recommended?

A: Customization is recommended when your application requires specific film thickness or substrate coverage that standard sizes do not meet. Custom diameters and lengths can be requested to align with unique process parameters or specialty projects.Q: Where can Wire Bar Coaters be used?

A: These coaters are ideal for laboratory R&D settings, quality control laboratories, and small-scale production environments within industries that handle paints, adhesives, inks, or similar wet media. They are widely available from manufacturers, distributors, and suppliers throughout India.Q: What is the cleaning process for Wire Bar Coaters?

A: Wire Bar Coaters should be promptly cleaned after use with suitable solvents that are compatible with the coated media. Use the optional cleaning brush for thorough results, ensuring the wire and rod remain free from residue to preserve coating accuracy and corrosion resistance.Q: What are the key benefits of using Wire Bar Coaters?

A: Wire Bar Coaters deliver precise, repeatable film thickness control with manual operation, eliminating power supply needs. Their ergonomic design enhances comfort, while the smooth and burr-free finish ensures safety. Conformance to ISO and ASTM standards guarantees dependable results for various laboratory and quality control activities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bar Coaters & Film Applicators Tools Category

Leveling and Sagging Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 010 mm groove depth (12 channels)

Material : Stainless Steel frame with precisionground surface

Range : 010 mm (Sagging and Leveling measurement)

Temperature Range : Ambient Conditions 10C to 45C

Automatic Film Applicator

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Measurement Range : 05 mm

Material : Stainless steel and anodized aluminum

Range : Film thickness range: 05 mm

Temperature Range : Ambient: 5C to 40C

Four Sided Film Applicator

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 4 Different Preset Film Thickness Options

Material : Highgrade Stainless Steel

Range : 4 Film Thickness Options

Temperature Range : Room Temperature Application

Film Applicator With Holding Device

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 10 mm to 300 mm (Film Width)

Material : HighGrade Stainless Steel and Aluminium

Range : Applicable for Standard Test Panels

Temperature Range : Ambient Operating Conditions

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS