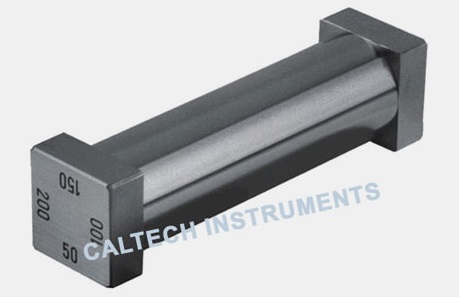

One Sided Film Applicator

Price 50 INR/ Unit

One Sided Film Applicator Specification

- Equipment Type

- One Sided Film Applicator

- Humidity %

- Recommended: 085% RH (non-condensing)

- Measurement Range

- Thickness range: 5/10/15/20/25/50/100/150/200/300/500/1000 microns (custom options available)

- Capacity

- Width options: 50/75/100/150 mm (custom widths available)

- Temperature Range

- Room temperature operation (not designed for elevated temperatures)

- Resolution

- 5 microns (varies by gap preset)

- Material

- High-grade stainless steel and anodized aluminium

- Power Supply

- Manual operation, no external power required

- Accuracy

- 2 microns (depending on coating material and technique)

- Range

- Film thickness: 02000 microns (varies by model)

- Usage

- Laboratory, R&D, Quality Control

- Weight

- Approx. 450g

- Surface Finish

- Smooth Polished

- Application

- For uniform film application on substrates

- Adjustability

- Fixed / Adjustable gap options

- Applicator Type

- One Sided

- Film Width

- 80 mm or Custom Sizes Available

- Cleaning

- Easy to disassemble and clean

- Film Thickness Range

- 10 - 300 microns

One Sided Film Applicator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Middle East, Central America, Western Europe, Africa

- Main Domestic Market

- All India

About One Sided Film Applicator

One Sided Film Applicator

Caltech india offers Single Side Film Applicator.

The Bar-Type One Sided Film Applicator is made using modern technology of metallurgy with a precision grinding machine. The accuracy of the Gap Depth is 1.0m50m and belowand or 2% of Full Scale. It is designed with ASTM D823-25 and ASTM D3022.

It is made of high-grade, corrosion-resistant stainless steel 440C.

Precision and Versatility in One Device

This film applicator delivers uniform coatings with exceptional accuracy. Available in both standard and custom widths, it accommodates various substrate sizes. Its adjustable or fixed gap options give users flexibility suited to their specific application, from quality assurance tasks to innovative laboratory experiments.

Rugged Build, Easy Maintenance

Manufactured from durable stainless steel and anodized aluminium, this applicator is built to last. Its design allows for fast disassembly, streamlining cleaning processes and helping maintain sample integrity across repeated uses. The smooth, polished surface finish further simplifies upkeep.

Manual Operation for Simplicity and Control

Designed for use in controlled environments at room temperature and 085% RH (non-condensing), this equipment operates manually, requiring no external power. This ensures total user control over film thickness, with resolution down to 5 microns depending on the setting.

FAQs of One Sided Film Applicator:

Q: How does the One Sided Film Applicator ensure uniform film application?

A: The applicator features a precisely engineered gap, available in fixed or adjustable formats, ensuring consistent film thickness across the substrate. Its smooth polished surface and controlled manual operation contribute to even distribution and accuracy within 2 microns, depending on coating material and technique.Q: What substrates or materials can I use with this applicator?

A: This film applicator is suitable for a wide range of substrates commonly used in laboratories and quality control settings. It can be used with films ranging from 10 to 300 microns thick and is compatible with various coating materials, as long as room temperature and humidity recommendations are followed.Q: When should I use the adjustable gap feature instead of the fixed gap?

A: The adjustable gap feature is ideal when you need to accommodate various film thicknesses or customize your coating process for different materials. Use the fixed gap for repeatable, standardized applications where consistent thickness is critical.Q: Where is this film applicator best suited for use?

A: This equipment is designed for use in laboratories, R&D facilities, and quality control departments. Its manual operation and recommended room temperature use make it suitable for controlled, indoor environments typical of research and testing institutions.Q: What cleaning and maintenance procedures are recommended?

A: The applicator is designed for easy disassembly, allowing thorough cleaning after each use. Clean all surfaces with appropriate solvents or mild detergents suitable for stainless steel and anodized aluminium, and ensure it is dried fully before reassembly.Q: How do I select the appropriate width and measurement range for my application?

A: Choose the film width and measurement range based on your substrate size and required film thickness. Standard options include 80 mm width and thickness from 10300 microns, but custom sizes and ranges can be requested to meet specific project needs.Q: What are the main benefits of using this one sided film applicator?

A: The key benefits include precise, consistent film application, customization options for width and thickness, user-friendly manual operation, durable construction, and easy maintenancemaking it highly effective for laboratory, R&D, and quality assurance work.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bar Coaters & Film Applicators Tools Category

Leveling and Sagging Tester

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : High, as per ISO 71, ASTM D4400 standards

Range : 010 mm (Sagging and Leveling measurement)

Power Supply : Not Applicable (Manual Operation)

Equipment Type : Leveling and Sagging Tester

Automatic Film Applicator

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Accuracy : 0.01 mm

Range : Film thickness range: 05 mm

Power Supply : AC 220V, 50Hz

Equipment Type : Automatic Film Applicator

Four Sided Film Applicator

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : High Precision Film Application

Range : 4 Film Thickness Options

Power Supply : Manual Operation (No Power Required)

Equipment Type : Four Sided Film Applicator

Film Applicator With Holding Device

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : High Uniformity in Film Thickness

Range : Applicable for Standard Test Panels

Power Supply : Not Applicable (Manual Operation)

Equipment Type : Film Applicator with Holding Device

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS