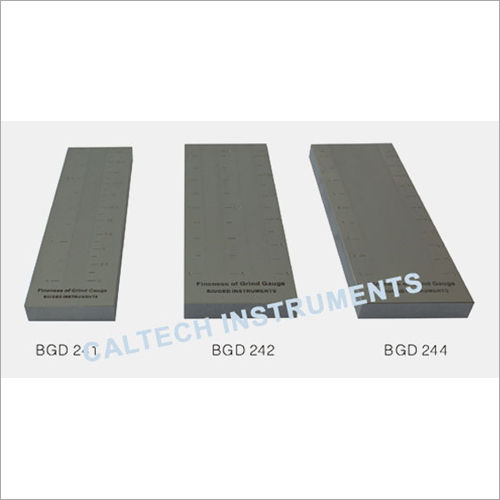

Fineness of Grind Gauge

Price 50 INR/ Unit

Fineness of Grind Gauge Specification

- Temperature Range

- Ambient

- Pressure Range

- Atmospheric

- Application Media

- Paints, Pigments, Inks, Coatings, Cosmetics, Chemicals

- Diameter

- Width: approx. 25100 mm (varies by model)

- Equipment Type

- Fineness of Grind Gauge

- Protection

- Corrosion-resistant Material

- Resolution

- 1 micron

- Measurement Range

- 025 microns (varies by model)

- Humidity %

- 0100% (Non-condensing)

- Capacity

- Single/Double Channel Options

- Material

- Stainless Steel or Hardened Alloy

- Power Supply

- Not Required (Manual)

- Accuracy

- 1 Hegman Unit

- Display Type

- Engraved Scale

- Range

- 0 to 25 microns (Hegman Scale: 8 to 0)

- Indicator Type

- Scraper Blade (included)

- Surface Finish

- Mirror polished for easy cleaning

- Scale Graduation

- Precisely etched microns and Hegman scale

- Cleaning Method

- Solvent compatible for easy maintenance

- Length

- Approx. 150 mm (varies by model)

- Compliance

- Conforms to ASTM D1210, ISO 1524 standards

- Markings

- Laser marked for durability

- Calibration

- Supplied with calibration certificate (on request)

- Application

- Laboratory, Quality Control, R&D

- Operation

- Manual drawdown

Fineness of Grind Gauge Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Fineness of Grind Gauge

Fineness of Grind Gauges

Caltech India offers Fineness of Grind Gauges. Many types of solid materials must be ground or milled into finer particles for dispersion in appropriate liquid vehicles. The physical properties of the resulting dispersions, often called grinds, depend not only on the actual size of the individual particles, but also on the degree to which they are dispersed.

The Fineness Gauges are used to indicate the fineness of grind or the presence of coarse particles or agglomerates in a dispersion. It does not determine particle size or particle size distribution.

Grind gauges are used in controlling the production, storage, and application of dispersion products produced by milling in the paint, plastic, pigment, printing ink , paper, ceramic, pharmaceutical, food and many other industries.

The Fineness Gauges is a flat steel block in the surface of which are one or two flat-bottomed grooves varying uniformly in depth from a maximum at one end of the block to zero near the other end. Groove depth is graduated on the block according to one or more scales used for measuring particle size.

Precision Measurement for Diverse Industries

The gauge is engineered for accurate particle size determination, supporting paint, pigment, ink, coating, cosmetic, and chemical applications. Its precisely engraved scale ensures reliable readings from 0 to 25 microns (Hegman scale 8 to 0), making it indispensable in laboratory and R&D settings. Its corrosion-resistant materials and solvent compatibility simplify routine maintenance.

Effortless Operation and Maintenance

Users benefit from manual drawdown operation using the included scraper blade. The instrument requires no power supply, and its mirror-polished surface allows for rapid, thorough cleaning with compatible solvents. Laser-marked graduations enable durable, clear readings, and a calibration certificate is available for guaranteed measurement confidence.

Compliance and Versatility

Conforming to ASTM D1210 and ISO 1524 standards, the gauge assures quality and repeatability. Available in single or double channel models and various sizes (length: approx. 150 mm, width: 25100 mm), it meets the diverse needs of dealers, distributors, exporters, manufacturers, and service providers across India.

FAQs of Fineness of Grind Gauge:

Q: How is the Fineness of Grind Gauge used to measure particle size in laboratory applications?

A: To measure particle size, a sample of paint, pigment, ink, or similar media is placed on the engraved scale. Using the supplied scraper blade, the operator manually draws down the sample, observing the scale for the point at which full dispersion occurs, which indicates the particle fineness in microns or Hegman units.Q: What are the benefits of the mirror-polished finish on the gauge surface?

A: The mirror-polished surface ensures that cleaning is easy and residue-free, reducing contamination risk between samples. Its smooth finish allows for efficient maintenance using standard laboratory solvents and helps maintain measurement accuracy over time.Q: When should calibration be performed for the Fineness of Grind Gauge, and how is a certificate obtained?

A: Calibration should be performed periodically or whenever precise validation is required. A calibration certificate is available upon request from the dealer, distributor, or manufacturer, confirming the instruments continued accuracy for quality control purposes.Q: Where can the Fineness of Grind Gauge be sourced in India, and who typically supplies it?

A: This equipment is widely available from manufacturers, dealers, distributors, exporters, traders, and service providers throughout India, catering to research laboratories, industrial quality control departments, and R&D facilities.Q: What process ensures the accuracy and durability of the scale graduations on the gauge?

A: The scale graduations are precisely etched and laser-marked onto corrosion-resistant stainless steel or hardened alloy. This method guarantees high accuracy (1 Hegman unit) and exceptional durability, preventing wear even after prolonged use.Q: How does manual operation improve the reliability of grind measurements?

A: Manual drawdown using the scraper blade provides direct control over the measurement process, minimizing mechanical errors and allowing the operator to visually assess the point of full dispersion along the gauge scale, thus ensuring repeatable and reliable results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Performance Category

Flash Point Tester

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel (SS) body with heatresistant parts

Accuracy : 1C

Display Type : Other, Digital LED Display

Equipment Type : Flash Point Tester

Drying Time Recorder

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Powder Coated Steel & Aluminum

Accuracy : 1% of full scale

Display Type : Other, Digital/LCD

Equipment Type : Drying Time Recorder

Fineness of Grind Gauges

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : HighGrade Hardened Stainless Steel

Accuracy : 1 m

Display Type : Other, Engraved Graduated Scale

Equipment Type : Fineness of Grind Gauge

Hegman Gauge

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : HighGrade Stainless Steel

Accuracy : 2 m

Display Type : Other, Engraved Scale

Equipment Type : Hegman Gauge

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS